Researchers Dr. André Anders and Dr. Yuchen Yang have expanded on their previous imaging work on linear magnetron cathodes. In their most recent work, titled “Plasma studies of a linear magnetron operating in the range from DC to HIPIMS,” the authors put forth additional information on the evolution and movement of spokes with several deposition materials and discharge conditions.

Using a linear magnetron coupled with a streak camera with its entrance slit aligned to the racetrack of the cathode, the duo has successfully imaged the evolution of instabilities in the sputter plasma. While these instabilities have been studied extensively in small, disc shaped cathodes, the authors seek to make observations which may be more industry relevant, as linear cathodes tend to dominate commercial thin film production. In this work sputter targets of various thicknesses were also employed, as the strength of the magnetic field at the cathode surface can have distinct effects on plasma properties especially in HIPIMS.

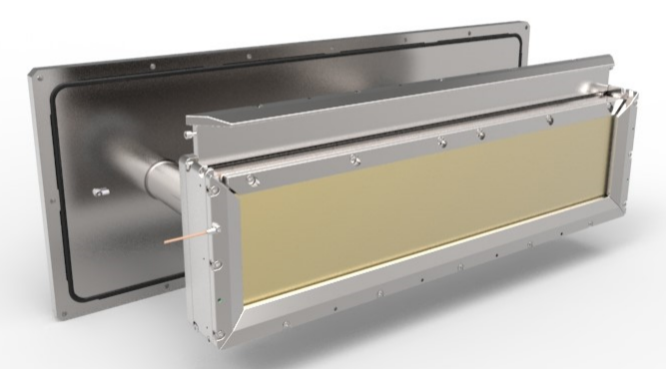

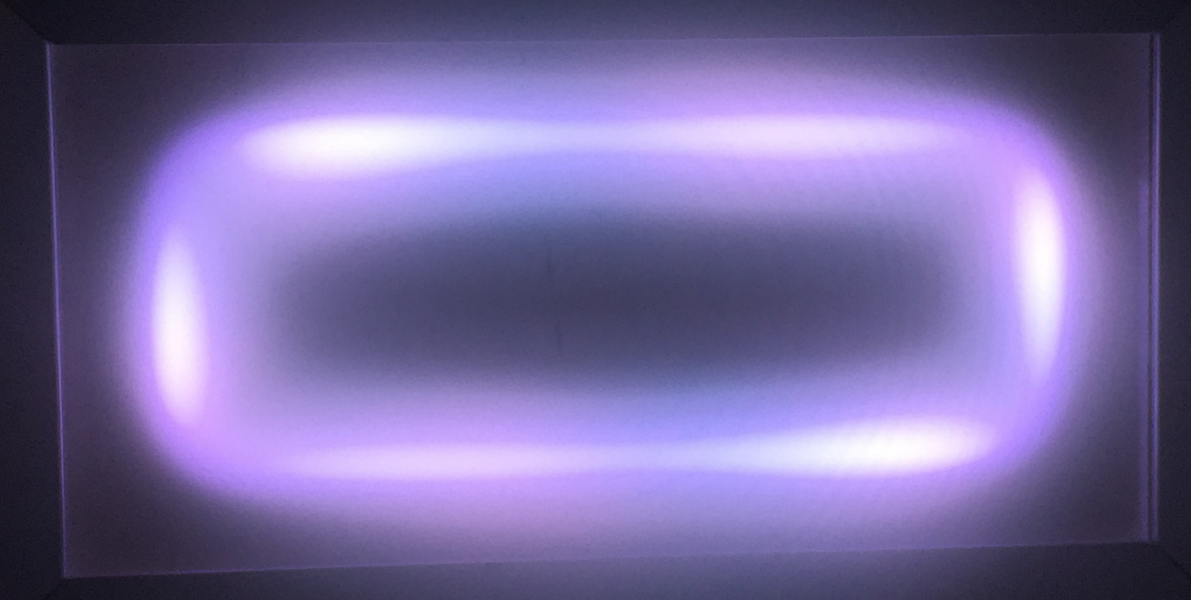

This work was based on the newly re-designed linear magnetron cathode manufactured by the Kurt J. Lesker Company. Although this cathode is available in lengths up to 160 inches, a version measuring 240 mm x 120 mm was used to accommodate the researcher’s deposition system. The Lesker linear cathode utilizes a unique drop-down anode target clamping design which facilitates easier target change-out and is optimized for enhanced erosion and uniformity profiles. The cathode supports conventional DC magnetron, RF, pulsed DC and HIPIMS sputter modes.

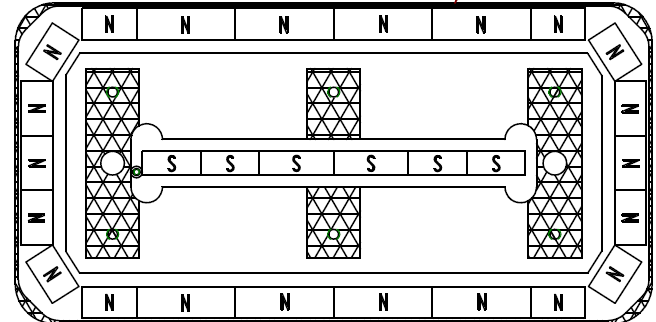

The Lesker linear magnetron design uses an array of magnets that are optimized in a north (+) south (-) north (+) configuration which has the secondary electrons, formed in the production of the sputter plasma, typically moving in the E x B direction—that is a direction perpendicular to the electric field E and to the magnetic field B. A preferred electron motion zone leads to a region of enhanced plasma production, and the underlying target area is preferentially sputtered, which in turn leads to the formation of the “racetrack” on the target.

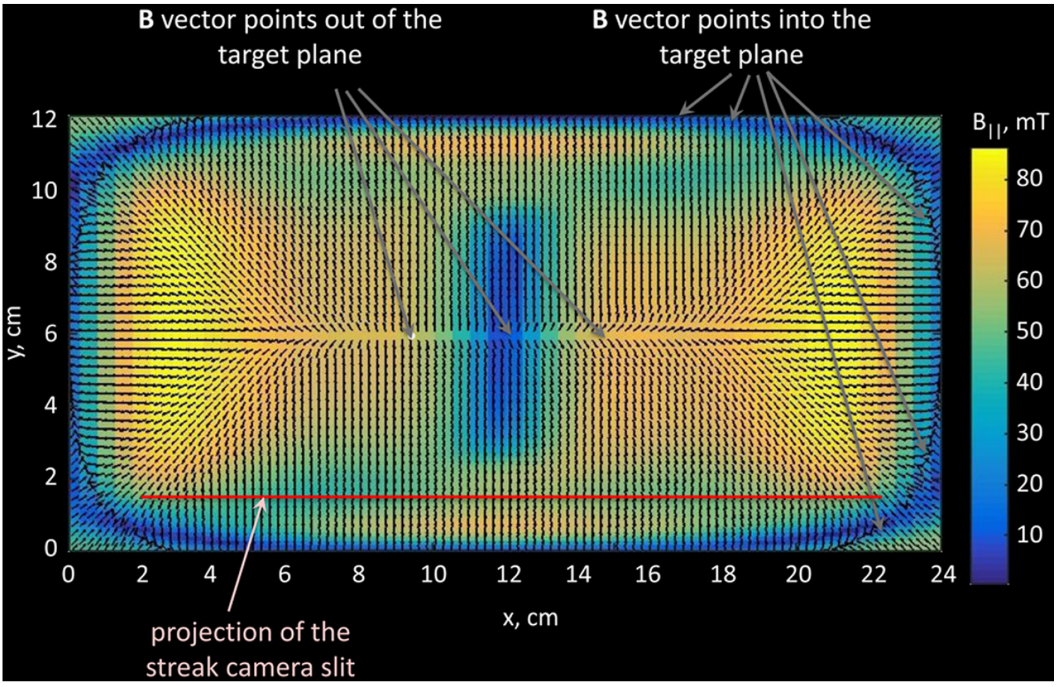

In order to better understand the specifics of the magnetic field of the cathode the authors mapped the B field normal to the surface at a height of 1 mm using a Hall probe for a 3 mm thick target. The magnetic field along the straight sections of the target varies in intensity by about +/- 10% which is typical for complex magnetic arrays. However, this variation may play a role in the formation of what the authors describe as ‘primordial’ spokes.

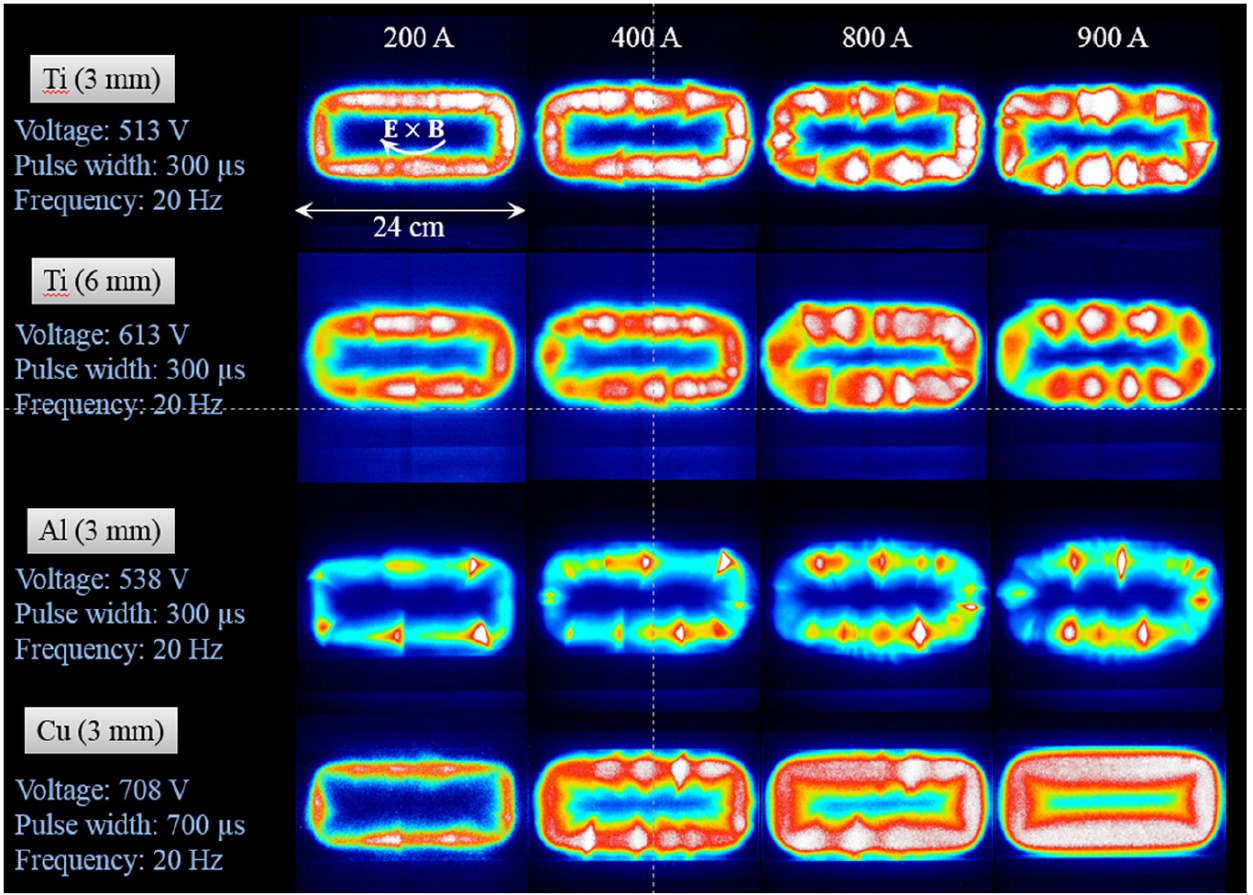

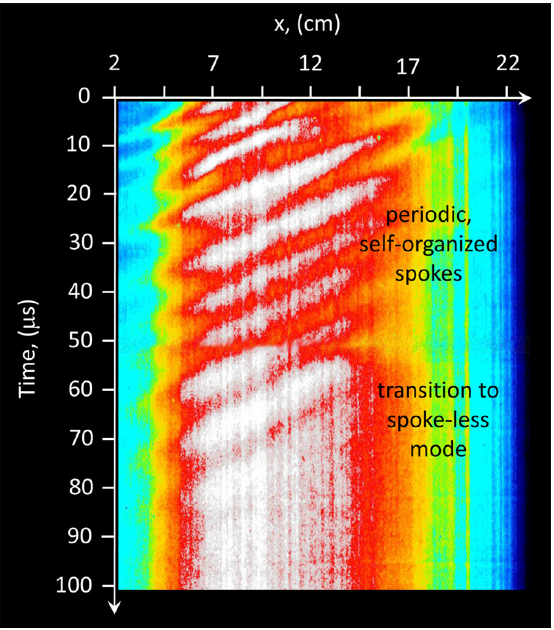

The authors were able to generate differing spoke patterns based on variations in power and also target thickness. In general, using conventional DC magnetron sputtering, they were able to image spokes flow in the — E x B direction (that is clockwise over the closed racetrack). At higher powers the number of spokes was reduced but their speed of movement increased. The electrons generally travel in the opposite, or E x B direction, which is the direction of the electron drift (counter-clockwise over the racetrack).

The formation and character of spokes also appears to be material dependent.

Previously, Anders and his co-authors have reported the extraordinary self-sputtering characteristics of copper metal targets. After initially using a process gas such as argon to initiate a plasma, in certain HIPIMS conditions the metal will self-sputter—that is, a sufficient number of sputtered target atoms are ionized in the HIPIMS discharge, so that they return to the target surface and dislodge more target atoms. At this point the process gas can be eliminated and the sputtering can proceed in vacuum.

In this work electron velocities were measured in the range of 5,000 meters/second up to 104 m/s. There is some evidence to support the idea that spoke velocity slows down at the corners and is generally constant in the straight regions of the race track. Of the target ions detected in this experiment, the ones generated in the straight regions of the racetrack have more energy than those generated at the curves. In HIPIMS mode the changes in velocity are not as apparent. With respect to ionization species, the authors report that sputter target ions are typically produced within 1 mm of the target surface while various species of gas ions, for example Ar+ and Ar+2 are produced at distances significantly beyond 1 mm.

In this work spokes are identified as ‘locations of enhanced excitation and ionization’ and not necessarily the same as the motion of charged particles. The authors have imaged the splitting and also the merging of spokes, sometimes at ‘infinite velocities’ which further supports the distinction that they are not simply charge particles in motion, but waves of ionization.

In future work the authors intend to provide additional simulations of the number and collision potential of ionized copper target atoms sufficient to move charged articles across B-field lines. They will also do additional studies on the ‘strangely reproducible differences’ ion energy distribution functions (IEDF) present in the plasma. In addition they intend to look at the effect of thickness (and magnetic field strength) on the differences in IEDFs in the straight vs. curved sections of the racetrack. A reduced magnetic field seems to minimize the differences in IEDFs.

This work confirms that spokes are present in every region of the magnetron plasma in most operating conditions. The extraordinary sputter yield achievable with copper in HIPIMS mode is an exception. In the future it is hoped by this reviewer that Anders and his team begin to explore the implications on film uniformity and morphology based on the production or elimination of spokes in both DC and HIPIMS sputtering modes. It would also be interesting to identify other materials, like copper, which exhibit self-sputtering such that process gases can be eliminated.

Figure 6. Streak camera imaging showing the transition, in copper, from spoked to spokeless modes.