TORUS® Mag Keeper™ UHV Compatible Circular Magnetron Sputtering Sources

Applications:

- R&D

- Optics

- Decorative

- Medical

- Sensors

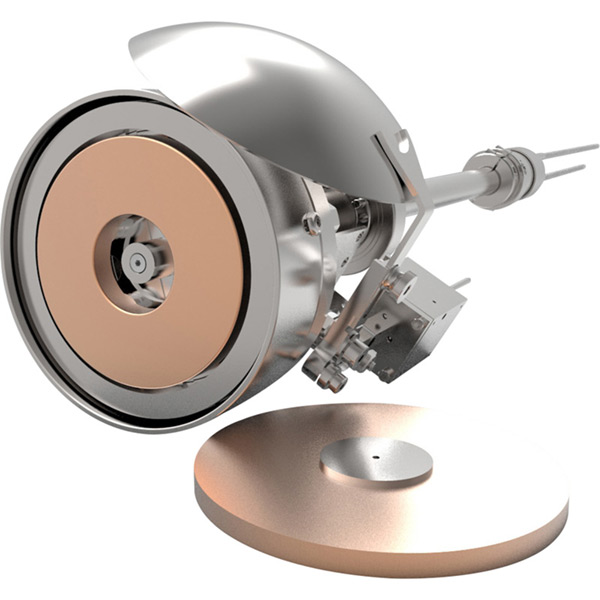

KJLC's Mag Keeper is designed to enable higher operating powers due to a mechanically enhanced cooling well. It is ideal for use in high throughput requirements and also enables quick target change with its magnetic keeper design, which secures the target to the source. The design has NO o-rings and utilizes ceramic insulators, making it both UHV and high temp compatible.

Overview

The Mag Keeper™ design is the latest addition to our TORUS® family of sputtering magnetron solutions. It is offered for target sizes of 2", 3", and 4". The magnetron design utilizes both monolithic and bonded target configurations up to 0.375" thick.

All targets (except for magnetic materials) utilize a bolt-on magnetic "keeper" assembly to fasten the target to the magnetron, which eliminates the need for a target clamp assembly. All bonded targets require an "elastomer" bond.

The magnetron does not utilize an independent "anode shield assembly" that needs to be removed. Instead, there is only an anode wall that sits below the target surface eliminating material build-up and flaking onto the target surface.

Our patented cooling well is the heart of the design, which enables operation at power densities ≥200 watts/.in2.

The assembly has NO o-rings and utilizes a single metal seal making it not only UHV compatible, but also capable of handling higher heat loads than our standard TORUS® design. Its smaller overall footprint also enables us to fit more sources into our standard chamber models.

The assembly is offered with both Standard and High Strength magnet options, which all fit the same cathode design. This allows for easy magnetic optimization of the sources in the field and also provides the ability to integrate an unbalanced field if required.

Features

- Compact Design

- HV and UHV Compatible

- Quick Target Change (No clamp or shield)

- Can sputter targets up to 0.375" thick

- High Mag design can sputter up to 0.100" thick Fe (TMK3 and TMK4)

- Low Operating Pressure - Can run ≤ 1mTorr

- No O-ring seals

- High Power/ High Rate capability

Specifications

| Magnet Assembly | High strength, rare earth NdFeB (Neodymium Iron Boride) |

| Power Rating | Capable of operating at power densities ≥200 watts/in2 (Max powers will vary based on target material properties) Upper level power densities may require the use of a thermal medium. |

| Operating Pressure | 0.5-50 mTorr |

| Target Sizes | 2", 3", and 4" OD |

| Target Thickness | Accomodates up to 0.375" |

| Target Change | No target clamp or top anode shield |

| Magnet Modification | Quick change magnet assembly |

| Seals | No o-rings - magnets NOT exposed to cooling water |

| Target Utilization | Typical utilization in the 30% range (with Non-Magnetic materials in a non-reactive mode) |

| Vacuum | HV and UHV |

| Worldwide Technical Support | Headquarters in USA, Canada, Europe and China |

| Warranty | All products covered by a 1-year warranty |

Low Pressure Sputtering Capability

Sputtering at low pressures can provide both process and performance advantages. At lower pressures, you have less Argon Ions in the chamber, which creates an enhanced mean free path for the Target Atoms ejected toward the substrate. At higher pressure, where there is more Ar Ions, sputtered atoms will incur more collisions reducing yield to the substrate and increasing material deposition on the chamber walls. This will ultimately reduce the sputtering rate and overall efficiency of the process.

Less Argon Ions also reduces argon inclusion in the resultant films. The enhanced mean free path will result in more target atoms reaching the substrate at an increased arrival energy.

Typical sputtering operating pressures fall in the 3-5 mTorr range.

Mag Keeper sputtering sources offer several key benefits for its users:

- No top target clamp - means purer deposition flux and no particulate generation.

- No top dark space shield to protect the target clamp - means minimized arcing/shorting issues associated with flakes falling from the dark space shield onto the target.

- Runs at intrinsically lower pressures than sputtering guns with target clamp/dark space shield assemblies - means more line of sight deposition, less argon incorporation in films.

- Rapid target change - no screws, clamps, or tools necessary to change targets.

We ran tests with our Torus 3 Mag Keeper with various targets to confirm the minimum operating pressures while trying to maintain a voltage of ≤ 600V. As a result, these results don't show the absolute minimum operating pressure. Please reference the table below.

Note: Process gas integration through standard system flow dynamics and not optimized locally at the target surface through secondary injection tubes.

Low Sputtering Pressure for 3" Diameter MagKeeper Targets

| Target Material | Flow Rate (sccm) | Pressure (mTorr) | Voltage (-V) | Power Supply | Comments |

|---|---|---|---|---|---|

| SiO2 | 16 | 0.39 | 642 | RF | – |

| ITO | 22 | 0.57 | 356 | PDC | – |

| ITO | 19 | 0.50 | 449 | DC | – |

| ITO | 17 | 0.43 | 430 | RF | – |

| Ti | 18 | 0.43 | 421 | RF | – |

| Ti | 21 | 0.54 | 581 | DC | – |

| C | 21 | 0.57 | 674 | DC | – |

| Al | 30 | 0.80 | 425 | DC | Worn target |

| Al | 22 | 0.56 | 519 | DC | New target |

| Al | 16 | 0.45 | 503 | DC | New target with HS mag pack |

| Ag | 20 | 0.52 | 518 | DC | – |

| Mo | 25 | 0.64 | 488 | DC | – |

| Cu | 22 | 0.57 | 576 | DC | – |

| W | 24 | 0.62 | 540 | DC | – |

| Ni | 10 | 0.23 | 688 | DC | 1/8" thick target with HS mag pack |

| Ni | 23 | 0.62 | 541 | DC | 1/8" thick target with standard mag pack |

| Ni | 20 | 0.55 | 541 | DC | 1/4" thick target with HS mag pack |

| Fe | 26 | 0.68 | 520 | DC | 0.080" thick with HS mag pack |

| Fe | 100 | 2.69 | 593 | DC | 0.100" thick with HS mag pack |

Note: Low sputtering pressure is dependent on system configuration and not guaranteed to reach the exact values listed here.

Mounting Options

- Axial

- Right Angle

- Flex

Shutter Option

-

Compact Dome

- Low profile design, ideal for

configurations with limited space - Pneumatically actuated

- Low profile design, ideal for

Targets

Kurt J. Lesker Company provides a full line of high purity materials.

-

Metals: Typically drilled and tapped with keeper attached directly to the target.

- Tungsten and Tantalum targets require elastomer bonding to backing plates as they cannot be reliably drilled and tapped due to their hard, yet brittle nature.

- Magnetic materials: Directly install with no keeper.

-

Ceramics, alloys (depending on the alloy), fragile materials, etc: Require bonding to backing plates with keepers.

- This is material specific and KJLC an advise if it's unclear

- Review the power requirements on our web pages pertaining to max power allowed for various materials. Anything bonded will be 20 watts per square inch or less depending on the material.

- Bonded assemblies will need to be elastomer bonded as it is rated to 250°C whereas indium is only rated to 150°C.

Please contact our materials department by clicking here for a quotation on the targets you need for you application.

Start Your Configuration

Choose the series, size, magnet configuration, mounting, tube length, gas/chimney, shutter, and flange designtor. Next, compose the order code as shown, below.

Contact us by clicking here or +1 800 245 1656 to discuss your specific vacuum application and process equipment needs.

Ordering Table

Please reference the ordering table below for Magnetron Sputtering Sources that we generally have in stock in one of our global warehouses.

| Target Diameter (in) | Magnet Array | Mounting Style | Length (in) | Shutter | Part Number | Price | In Stock | Add To Cart | |

|---|---|---|---|---|---|---|---|---|---|

| Target Diameter (in) | Magnet Array | Mounting Style | Length (in) | Shutter | Part Number | Price | In Stock | Add To Cart | |

| 2 | High Strength | Flex Head | 10 | Pneumatic Compact Dome |

|

|

|||

| 4 | High Strength | Flex Head | 5.5 | Pneumatic Compact Dome |

|

|

|||

| 4 | Standard | Axial | 8.5 | Pneumatic Compact Dome |

|

|

|||

| 4 | Reversed Polarity High Strength | Flex Head | 5.5 | Pneumatic Compact Dome |

|

|

Accessories Table

| Accessory Type | Description | Reference | Notes | Part Number | Price | In Stock | Add Item | |

|---|---|---|---|---|---|---|---|---|

| Accessory Type | Description | Reference | Notes | Part Number | Price | In Stock | Add Item | |

| 1 | EJCBL3HN | $229.00 |

|

|||||

| 1 | EJCBL3NN | $114.00 |

|

|||||

| 1 | EJCBL3NP | $100.00 |

|

|||||

| 1 | EJCBL3NU | P.O.R. |

|

|||||

| - | PD500X1 | $6,250.00 |

|

|||||

| - | PD500X2 | $6,570.00 |

|

|||||

| - | PD500X3 | $6,984.00 |

|

|||||

| - | RF03A22XX300 | $9,895.00 |

|

|||||

| - | RF06A22XX300 | $14,150.00 |

|

|||||

| - | TMK00CC-MAGRT | $50.00 |

|

|||||

| - | TMK2CC-HS3RT | $75.00 |

|

|||||

| - | TMK3CC-HS3RT | $75.00 |

|

|||||

| - | TMK4CC-HS3RT | $75.00 |

|

|||||

| - | GA-0275I | P.O.R. |

|

|||||

| - | HCHM0610-020S4P0 | $3.50 |

|

|||||

| - | TMK2CC-00101 | $2,090.00 |

|

|||||

| - | TMK2CC-00710 | $567.00 |

|

|||||

| - | TMK2CC-ACCKIT | $20.00 |

|

|||||

| - | TMK2H | $502.00 |

|

|||||

| - | TMK2S | $256.00 |

|

|||||

| - | 58159 | $6.00 |

|

|||||

| - | HBHM0407-006S4PV | $1.85 |

|

|||||

| - | TMK00CC-00210 | $80.00 |

|

|||||

| - | TMK3CC-00101 | $2,291.00 |

|

|||||

| - | TMK3CC-00410 | P.O.R. |

|

|||||

| - | TMK3H | $590.00 |

|

|||||

| - | TMK3S | $425.00 |

|

|||||

| - | HCHM0812-030S4P0 | P.O.R. |

|

|||||

| - | PIC1808R | $1.00 |

|

|||||

| - | TMK00CC-00710 | $385.00 |

|

|||||

| - | TMK3CC-ACCKIT | $20.00 |

|

|||||

| - | TMK4CC-00101 | $2,614.00 |

|

|||||

| - | TMK4CC-00410 | $250.00 |

|

|||||

| - | TMK4H | $916.50 |

|

|||||

| - | TMK4S | $816.50 |

|